When it comes to the world of automotive wiring, accuracy and efficiency are critical. One small mistake in identifying the wrong wire could lead to costly repairs—or worse, dangerous electrical faults.

Enter color coding—a straightforward yet indispensable system that makes automotive wiring manageable, safe, and efficient. By ensuring that each wire is easily identifiable, color coding enhances safety, facilitates troubleshooting, and improves overall organization. Keep reading as we go into greater detail about the importance of color-coding automotive wiring.

Simplifying Troubleshooting for Automotive Professionals

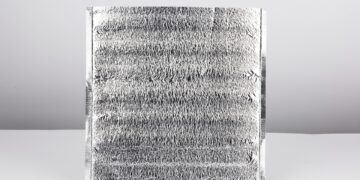

Color coding is also integral for identifying issues during troubleshooting. Automotive wire harnesses can contain hundreds of individual wires, which carry power and signals to various components in the vehicle. Without proper coding, locating the problem could feel like finding a needle in a haystack.

With color-coded wiring, identifying the problematic wire becomes far simpler and eliminates the need for trial-and-error testing. For example, if a headlight isn’t functioning, a technician can immediately pinpoint the wire associated with the headlight circuit just by following the appropriate color.

Speeding Up Repair Work for Technicians and DIYers

Why spend hours untangling wires or deciphering tangled blueprints when color coding can significantly speed up the repair process? Color-coding systems allow technicians to quickly locate, replace, or repair specific wires. This efficiency is particularly valuable in emergency situations, where time is of the essence.

A great example is the use of advanced connections like 10-cavity connectors for cars, which ensure seamless handling of multiple wires. When combined with effective color coding, these connectors simplify upkeep and repair tasks, save time and money, and enhance performance.

Better Organization for Automotive Wiring Systems

Organization may not seem thrilling, but in automotive wiring, it can mean the difference between functionality and chaos. A well-organized wiring system benefits the repair team but also reduces the likelihood of future problems developing. Color coding plays an essential role in creating and maintaining this organization.

By pairing it with cable management tools, like clips and sleeves, automotive professionals can design systems that are efficient, accessible, and easy to understand even years after installation. Better organization means fewer errors and higher reliability for the entire electrical system.

Whether it’s enhancing safety, speeding up repairs, or improving electrical system longevity, color coding is an invaluable tool in automotive wiring systems. It creates clarity and order in one of the most complex aspects of vehicle design and repair. By adopting a color-coded approach for wiring, professionals and car enthusiasts can work more efficiently, keep their vehicles safer, and ensure better system organization.