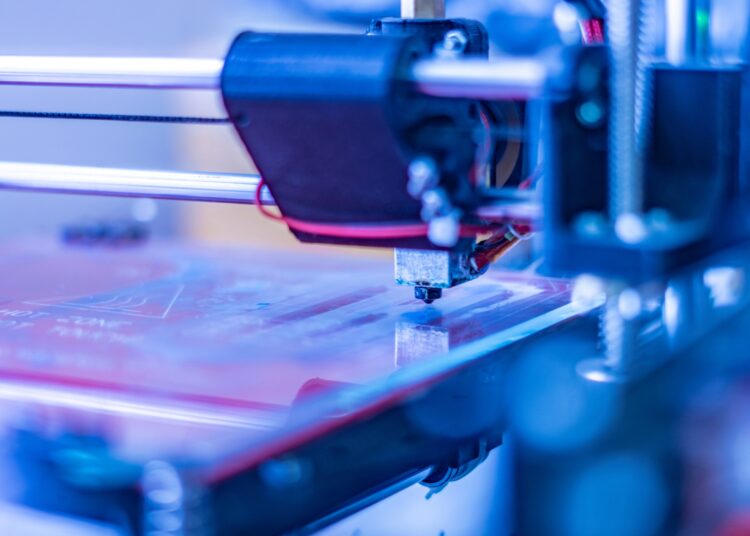

Custom manufacturing touches more sectors than you might expect. Multiple industries that rely on custom manufacturing depend on specialized production processes to create components that meet exact specifications.

These sectors need parts that standard mass production cannot deliver, requiring manufacturers who can adapt their processes to unique requirements.

Healthcare and Medical Devices

Medical equipment manufacturers require unmatched precision. Custom parts for surgical tools, diagnostic devices, and patient monitors demand precise tolerances and biocompatible materials. Hospitals depend on equipment that performs flawlessly under pressure, and custom manufacturing provides components that meet these strict standards.

Medical device companies often work with small production runs, but it’s crucial that they deliver high-quality results. Each component needs thorough testing and must meet regulatory approval standards.

Aerospace and Defense

Aircraft manufacturers cannot compromise on quality or precision. Every bolt, bracket, and housing component must meet strict engineering standards to withstand extreme conditions such as high altitudes, intense pressure, and rapid temperature fluctuations, all while maintaining structural integrity.

Defense contractors, on the other hand, require highly specialized parts that meet rigorous military specifications and adhere to strict security clearances. This is to ensure safety, reliability, and compliance with defense regulations.

Automotive Manufacturing

Car manufacturers rely heavily on custom components for prototype and production vehicles. These include engine housings, interior trim pieces, and other parts that must meet precise specifications and safety standards.

Electric vehicle makers mainly rely on custom manufacturing for battery enclosures, charging parts, and thermal management systems. These emerging technologies demand innovative manufacturing solutions that go beyond traditional processes.

Electronics and Technology

Consumer electronics firms depend on custom housings, connectors, and protective cases to improve their products. For smartphone makers, precision-molded parts are vital to safeguard sensitive internal circuits while sustaining a sleek and modern appearance.

Achieving a balance between production speed and component quality is essential, with factors such as tooling costs, lead times, and material properties influencing these decisions.

Industrial Equipment

Heavy machinery manufacturers depend on custom parts for specialized applications. Construction equipment, manufacturing machinery, and processing equipment all require components designed for specific operational environments.

These industries often need parts that can handle:

- High-pressure environments

- Chemical exposure

- Extreme temperatures

- Heavy mechanical loads

Marine and Maritime Applications

Boat builders and marine equipment manufacturers face unique challenges from saltwater exposure and harsh ocean conditions. Custom manufacturing provides components with specialized coatings and materials that resist corrosion while maintaining structural strength.

Maritime safety equipment requires custom parts that function reliably in emergencies. Life-saving devices cannot fail when lives depend on them, making custom manufacturing processes important for this sector.

The industries that rely on custom manufacturing continue expanding as technology advances and specialized applications grow. These sectors drive innovation in manufacturing processes, pushing the boundaries of what custom production can achieve. Companies across these industries depend on manufacturing partners who understand their unique requirements and can deliver components that meet demanding specifications.