It’s not always easy to get high-quality prints. You’ll need patience and some fine-tuning to get to know your printer and the filament you want to use. When dealing with quality issues, we recommend looking at your setup and changing only one thing at a time before trying a fresh print. Then, make a note of the modification and how it differs from the prior print. You won’t know which adjustment made a difference if you make too many changes at once! Here are our top tips for accurately printing with PLA.

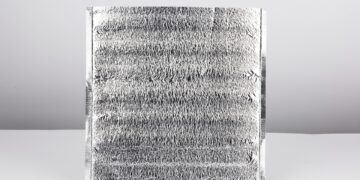

Upgrade Your Build Surface

The build plate is an important component of your printer that influences the materials you can print with and the surface of your print creations. On the bottom of the print, different build plates provide distinct textures: Glass, PEI, or Kapton tape leaves a smooth finish on the bed, whereas glue-on polycarbonate sheets and painter’s tape leave a matte finish. If you’re using a spray or glue to adhere the print to the surface, only use enough to adhere to the print. It’s also tough to remove the print if there’s too much glue or spray on it. Forcing it off could harm the print or break or deform the plate if applied with enough force.

Print Slower

PLA can achieve blazing print speeds with proper fan cooling. Try printing a little slower if you’re having issues with interlayer adhesion or print quality. If you print at speeds faster than 80mm/s, your printer may struggle to lay down filament quickly enough. Layers may not adhere to one another, resulting in sloppy prints and low surface resolution. We’ve discovered that printing at a speed of 55mm/s or slower produces excellent results. It represents the sweet spot for us in terms of print speed and surface resolution.

Flow Control

PLA is susceptible to over-extrusion. If you’ve followed all the instructions above but still have sloppy layers, the issue could be due to over extrusion. This happens when your printer extrudes more filament than it should, resulting in messy layers, and, in some situations, too much material on the hot end. To solve this problem, simply limit the filament flow by 5% at a time to avoid over extrusion. If you cut it too much, it will result in poor part strength and thin, wispy layers.

We hope you have enjoyed our tips for accurately printing with PLA. If you are looking to learn more about 3D printing and its common difficulties, be sure to check out our wide variety of resources to get the most useful information possible.