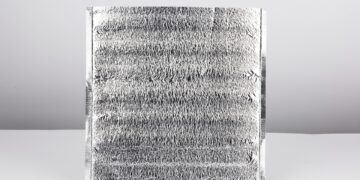

Tank liners serve a foundational role in many industries by protecting high-quality, expensive equipment. Whether you’re selecting a liner for your storage tanks or just want to learn more about this valuable equipment, you’ve come to the right place. Below, our guide will explain what tank liners are and their applications in sectors like chemical processing and the food industry.

Tank Liners, Explained

Tank liners are protective layers that apply to the interior surfaces of storage tanks. They create a barrier between the contents and the tank’s structural material, preventing corrosion, contamination, and leaks.

Made from materials such as thermoplastics, rubbers, and special composites, these linings are crucial for maintaining the integrity of tanks and the purity of their contents, especially when storing chemicals, water, or other sensitive substances. Essentially, they act as an internal shield, extending the tank’s life and ensuring safe, reliable storage.

Sectors That Utilize Tank Liners

Now that we understand what tank liners are, what are their applications? Many sectors utilize the tank liners to protect their storage tanks, including chemical processors and water treatment facilities.

Chemical Processing

Chemical manufacturers rely heavily on tank liners to prevent dangerous reactions between materials and tank walls. Liners eliminate the risk of metal contamination in sensitive chemical processes while protecting expensive storage infrastructure from corrosive damage. This protection proves especially valuable when storing acids, caustics, and specialty chemicals that would quickly destroy unprotected metal surfaces.

Food and Beverage Processing

The food and beverage sector also utilizes tank liners for food processing plants and breweries. Food industry applications demand liners that meet strict safety and hygiene standards.

These installations prevent metallic taste transfer, eliminate contamination risks, and simplify cleaning procedures. Dairy processing facilities, beverage manufacturers, and food ingredient suppliers depend on FDA-approved liners to maintain product quality and regulatory compliance.

Water Treatment Facilities

Municipal water treatment plants and industrial water processing operations use tank liners to prevent contamination and extend the lifespan of their infrastructure. These applications involve storing treated water, water-treatment chemicals, or wastewater that requires containment before processing. Liners ensure water quality remains uncompromised while protecting valuable treatment equipment.

Advantages That Drive Industry Adoption

Various industries require tank liners for storage equipment because they provide many benefits to equipment protection. Tank liners significantly reduce replacement costs by protecting the underlying tank structure from corrosion and chemical damage. This extends the equipment’s life by decades, allowing facilities to delay expensive tank replacements while maintaining operational reliability. The initial investment in a liner typically pays for itself by avoiding these replacement costs and reduced maintenance needs.

Liners also create an impermeable barrier that prevents product contamination from rust, metal ions, or chemical reactions with the tank walls, ensuring product quality and compliance with industry standards. Modern liners also feature smooth surfaces that simplify cleaning procedures, reduce downtime, lower cleaning chemical consumption, and minimize labor costs.

Protecting Your Investment

Tank liners represent a strategic investment in operational reliability and cost control. These protective systems transform vulnerable storage infrastructure into dependable, long-lasting assets that support consistent operations across diverse industries. Selecting the appropriate liner material and installation approach requires careful consideration of your specific storage requirements, operating conditions, and performance expectations.