On Friday nights across southern Ohio, the sense of community is unmistakable. Stadium lights flick on, and families pour into the bleachers, wrapped in school colors. School pride remains a powerful force in these towns, from football games to basketball tournaments. What’s changing, however, is how that school spirit gear is being made.

In recent years, small businesses across southern Ohio have begun embracing new production technologies to meet growing demand for locally made school spirit items. This shift is allowing print shops to compete with national vendors while keeping pride rooted in their own communities.

From Bulk Orders to On-Demand Production

Producing school spirit apparel came with built-in limitations for decades. Traditional screen printing required large minimum orders to justify setup costs. Embroidery added time and expense. Options were limited if a club needed shirts for a last-minute fundraiser. That reality no longer matches how schools operate today. Parents want gear quickly. Students want designs tied to specific moments like senior nights. New digital transfer technologies have filled that gap. Small businesses can now produce one-off designs with professional results, instead of committing to hundreds of units.

Why Small Businesses Are Leading the Shift

Southern Ohio’s business landscape is dominated by adaptability. Many local shops already wear multiple hats. Printing banners one week, creating custom gifts the next, and producing apparel when the season calls for it. New tech fits seamlessly into that flexible mindset.

With modern transfer solutions, a single shop can handle:

- A custom hoodie for a student athlete

- Twenty shirts for a club fundraiser

- Tumblers for a school event

- Limited-edition gear celebrating a big win

This versatility allows small businesses to say “yes” more often, strengthening relationships with schools and families who value responsiveness.

Raising the Bar for Design Quality

Speed is an advantage. The quality of today’s school spirit gear has noticeably improved thanks to advances in printing and transfer technology. Full-color designs are no longer reserved for large commercial vendors. Small shops can now deliver crisp, durable designs that rival national brands without outsourcing production. As expectations rise, so does demand. Students and parents increasingly want gear that feels well-made. Local businesses equipped with modern tools are stepping up to meet that standard.

Supporting Fundraisers and School Programs

Fundraising remains a cornerstone of school life in southern Ohio. Sports teams, music programs, academic clubs, and parent groups all rely on merchandise sales to support activities. New production methods make these efforts easier to support. Short runs become financially viable. Designs can be tested before committing. Updates can be made quickly if details change. Importantly, money spent on locally produced spirit gear often stays in the community. Those dollars support nearby businesses instead of flowing to distant vendors. Many of which are run by lifelong residents who have a personal stake in the schools they serve.

Expanding Beyond Shirts and Hoodies

Another major shift is the expansion of what counts as school spirit gear. Apparel is still popular, but it’s no longer the only option.

Southern Ohio makers are increasingly producing:

- Water bottle

- Custom tumblers and mugs

- Car window stickers

- Locker labels and signage

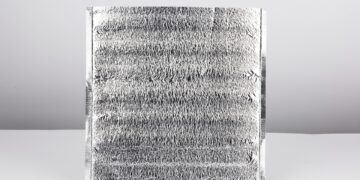

UV-based transfer technology has played a key role in this expansion, allowing designs to adhere cleanly to hard surfaces with a professional finish. This opens the door for new product categories that appeal to different age groups. Some local businesses source ready-to-apply options from suppliers. Visit – DTF Transfers Now, which offers UV DTF transfers that simplify production while maintaining durability and visual impact.

Competing With National Vendors Without Losing the Local Touch

National spirit wear websites still dominate search results, but they can’t match the flexibility and connection offered by local businesses. When customers buy locally, they benefit from easier communication. New technology allows small shops to stay competitive on quality while leaning into what sets them apart: personal relationships. Many customers know the owner by name, see them at games, or have children in the same schools. That trust matters, especially when details count.

Lower Risk, More Sustainable Growth

Modern transfer technology reduces risk from a business standpoint. There’s no need to stock large inventories or gamble on bulk orders that may not sell. Designs can be produced as needed. Trends can be tested without heavy upfront investment. This model supports sustainable growth, particularly for small or home-based businesses. It lowers barriers to entry, allowing entrepreneurs to scale gradually. Taking on larger projects as demand grows. In a region where small businesses are central to local economies, that stability matters.

Strengthening Community Identity Through Technology

This move towards technology is about community identity. School colors and slogans represent shared experiences. Local businesses become part of the fabric of community life when they help bring those symbols to life. New tech simply makes it easier to do that work well. It allows small businesses to respond quickly without losing their local roots.

Conclusion

Southern Ohio’s small businesses are likely to push further into custom, on-demand production as technology continues to evolve. Expect to see more personalized designs, more limited-edition releases tied to specific events, and deeper collaboration between schools and local makers. What won’t change is the pride behind it all. School spirit will always be about belonging. Thanks to new technology, local businesses are better equipped than ever to keep that spirit visible. One shirt or custom piece at a time.